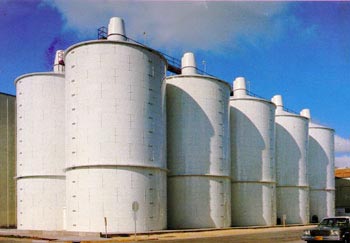

Sidewall

Every installation is designed to incorporate your specifications in a cost-effective and aesthetically pleasing system.

We evaluate insulation materials, such as polystyrene, fiberglass (requires additional panel stiffening), perlite, or foam glass, along with sheathing materials like aluminum, painted steel and stainless steel, that can be incorporated into the system. With every installation, we meticulously calculate wind load requirements and are attentive to every detail. We are also able to provide economic alternatives in addition to aesthetic changes.

Vertical Sidewalls

Thermacon’s vertical sidewall systems are ideal for both heated and cold storage applications. This system is available a two foot wide by full shell height panels, composed of foil-faced isocyanurate foam laminated to an aluminum outer sheathing.

We mechanically join these vertical panels in the field to form a weather tight standing seam. An internal cable and clip system within the standing seam secures the system to the tank wall.

The attachment system is installed without requiring welding, so the tank can be insulated while in service.

Whatever your operational or design requirements, we offer a wide range of architectural colors to meet them. This system requires very little continuing maintenance and is also conveniently pre-engineered.

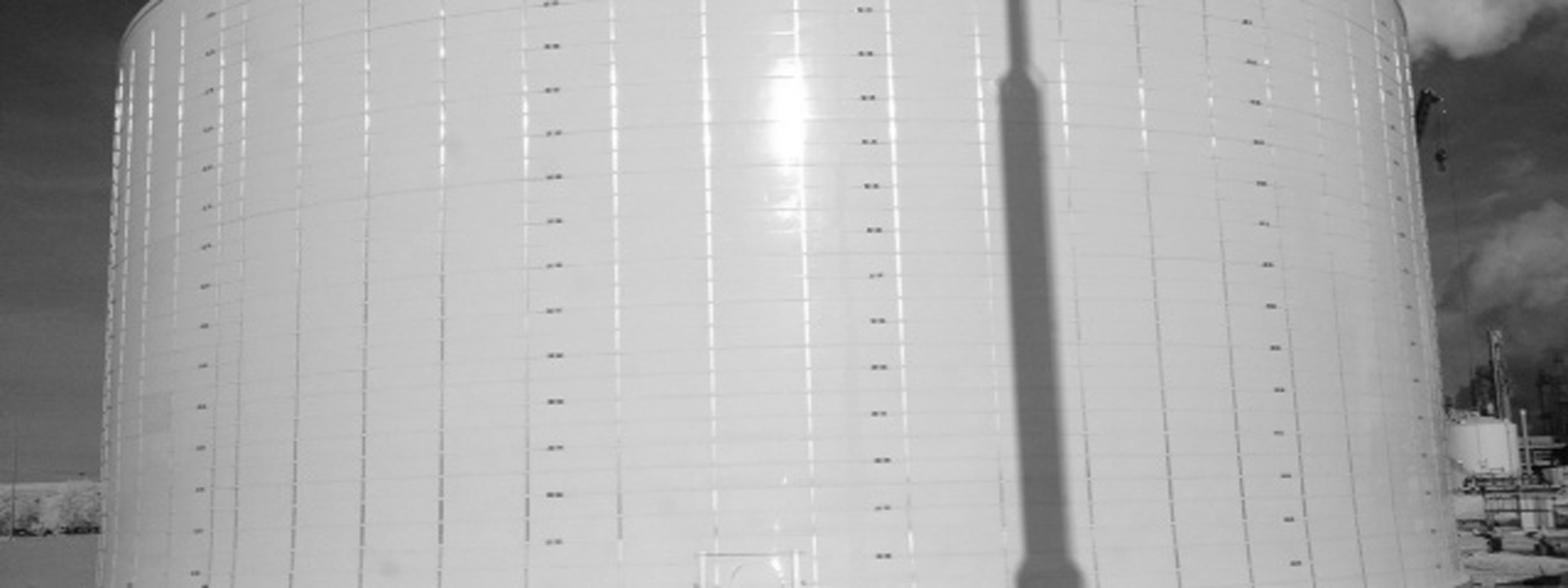

Horizontal Sidewalls

Our horizontal sidewall systems are pre-engineered composed of foil-faced isocyanurate foam insulation, laminated to an aluminum outer sheathing and factory curved to each tank’s radius. We offer a wide variety of finishes, thicknesses, and colors for our sheathing materials.

Because of Thermacon’s unique, state-of-the-art tensioned bandsion assemblies the system allows for operation expansion and contraction. Every panel is secured to the tank with 3″ wide aluminum or stainless steel external banding spaced on calculated intervals.

To ensure operational and design goals we allow for various insulation materials, such as polystyrene, fiberglass, perlite, or foam glass, along with outer sheathing materials options of aluminum, steel or stainless steel. All of our systems provide design details in order to ensure your project will conform to specific specifications to provide economic alternatives in addition to aesthetic changes.